Projects

- Home

- Belt Feeder In Bunker

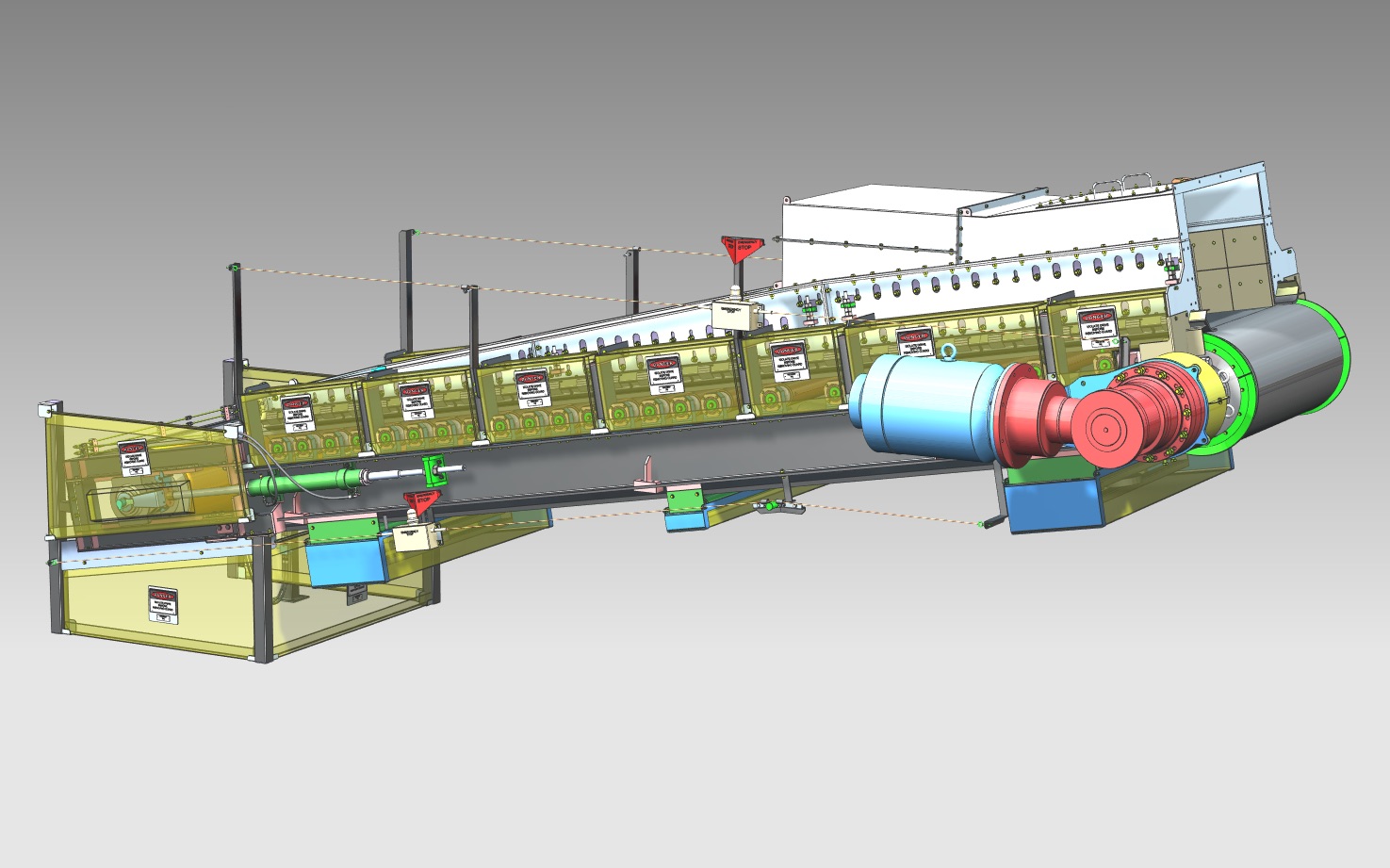

Belt Feeder In Bunker

Project Description:

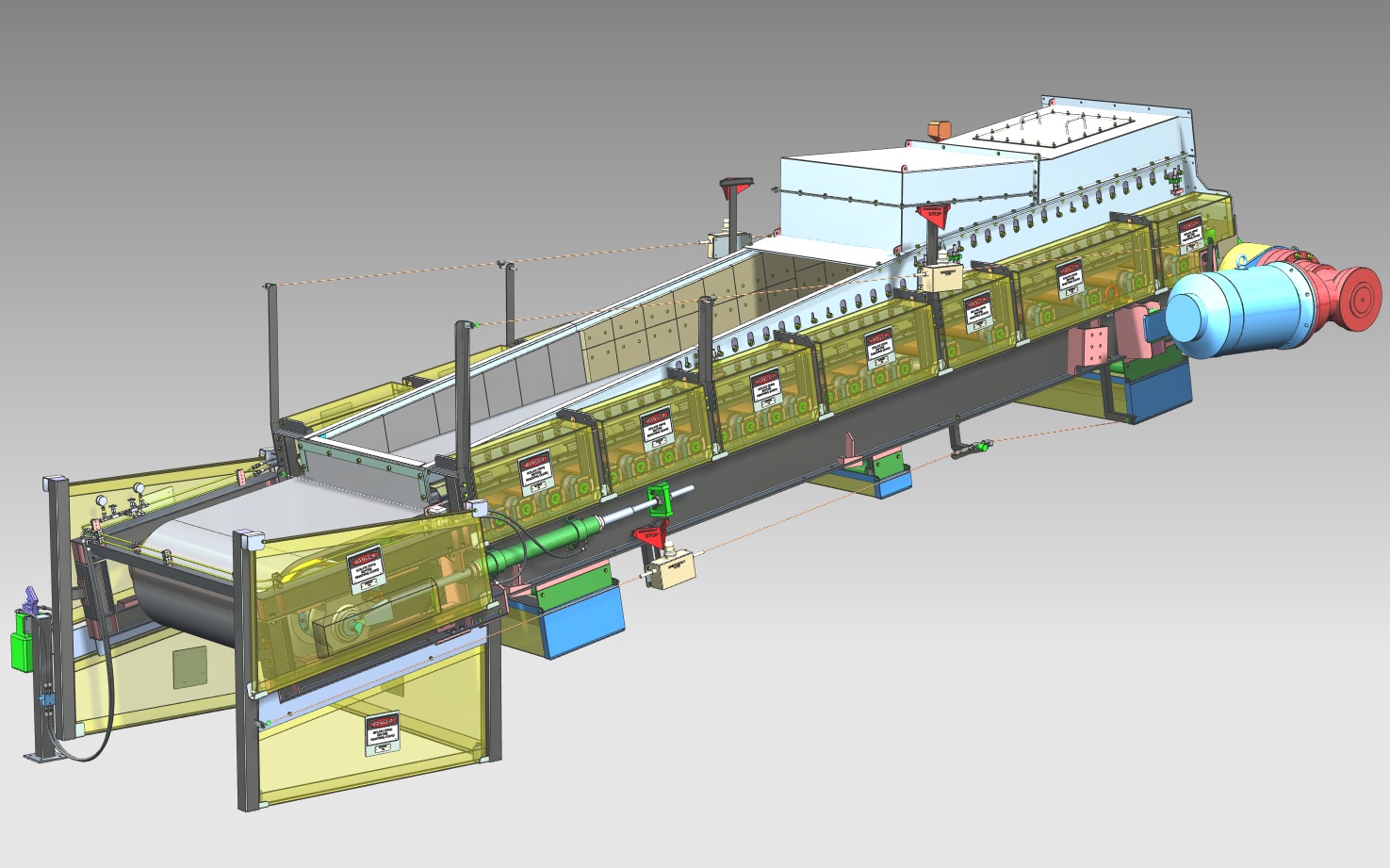

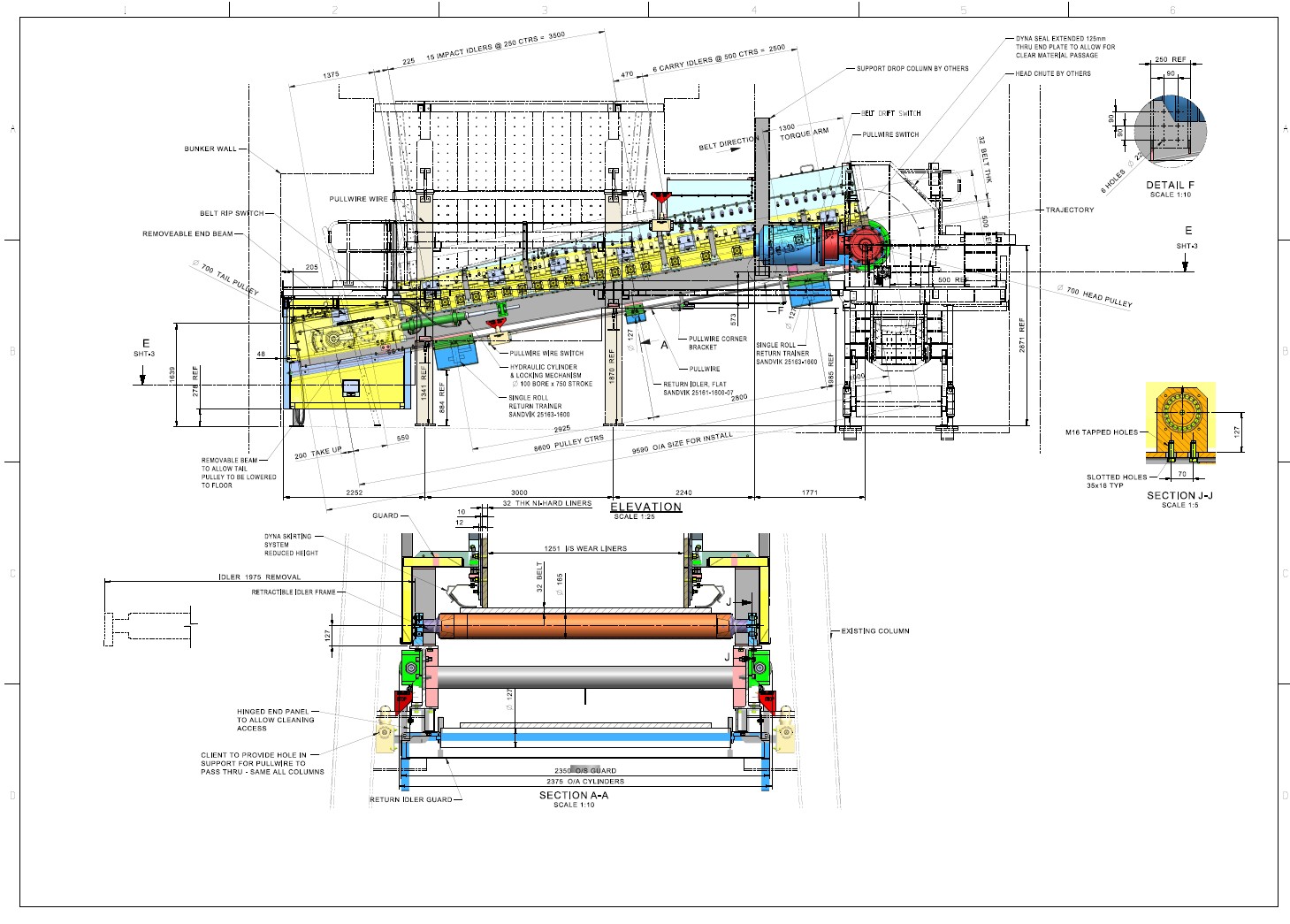

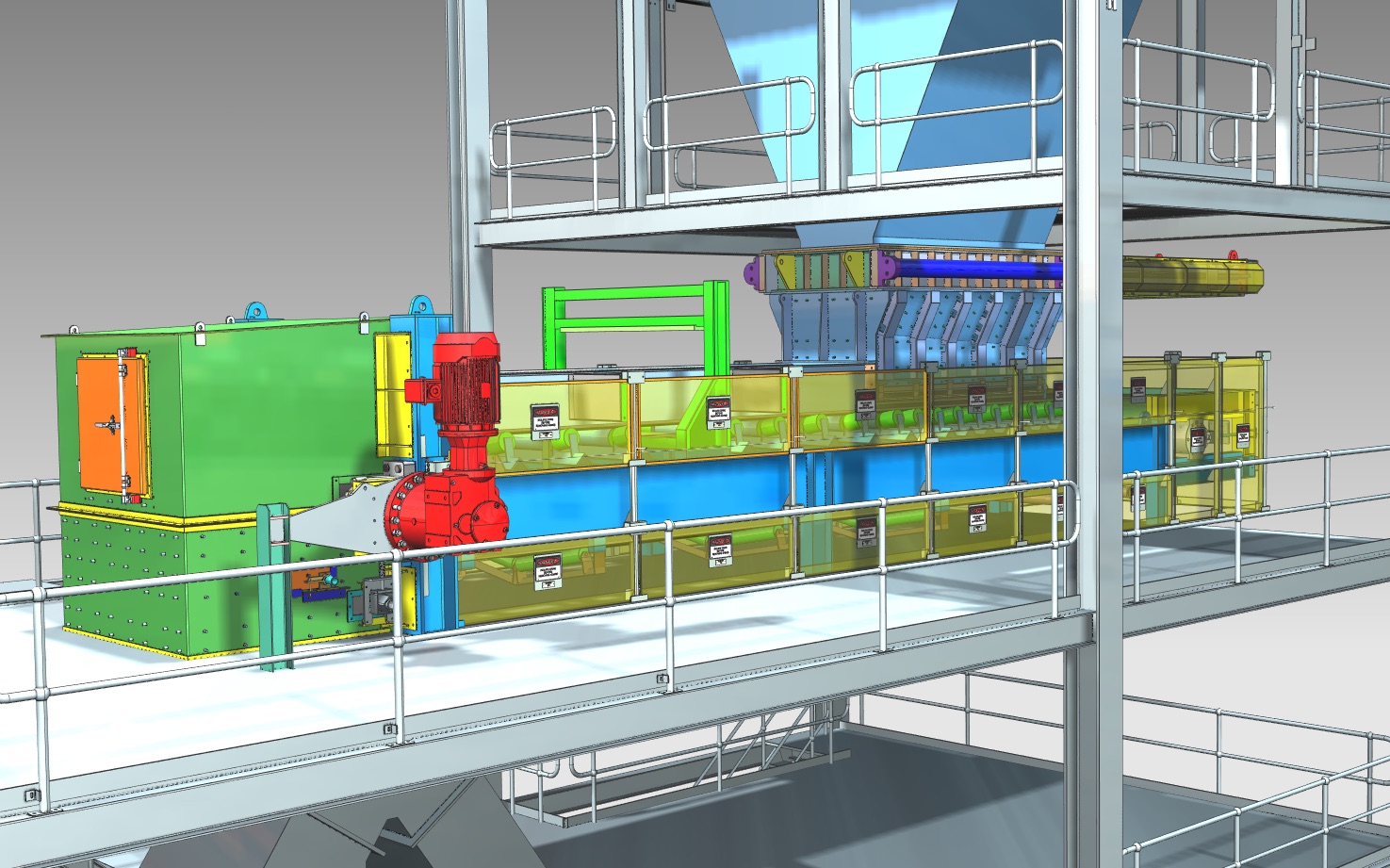

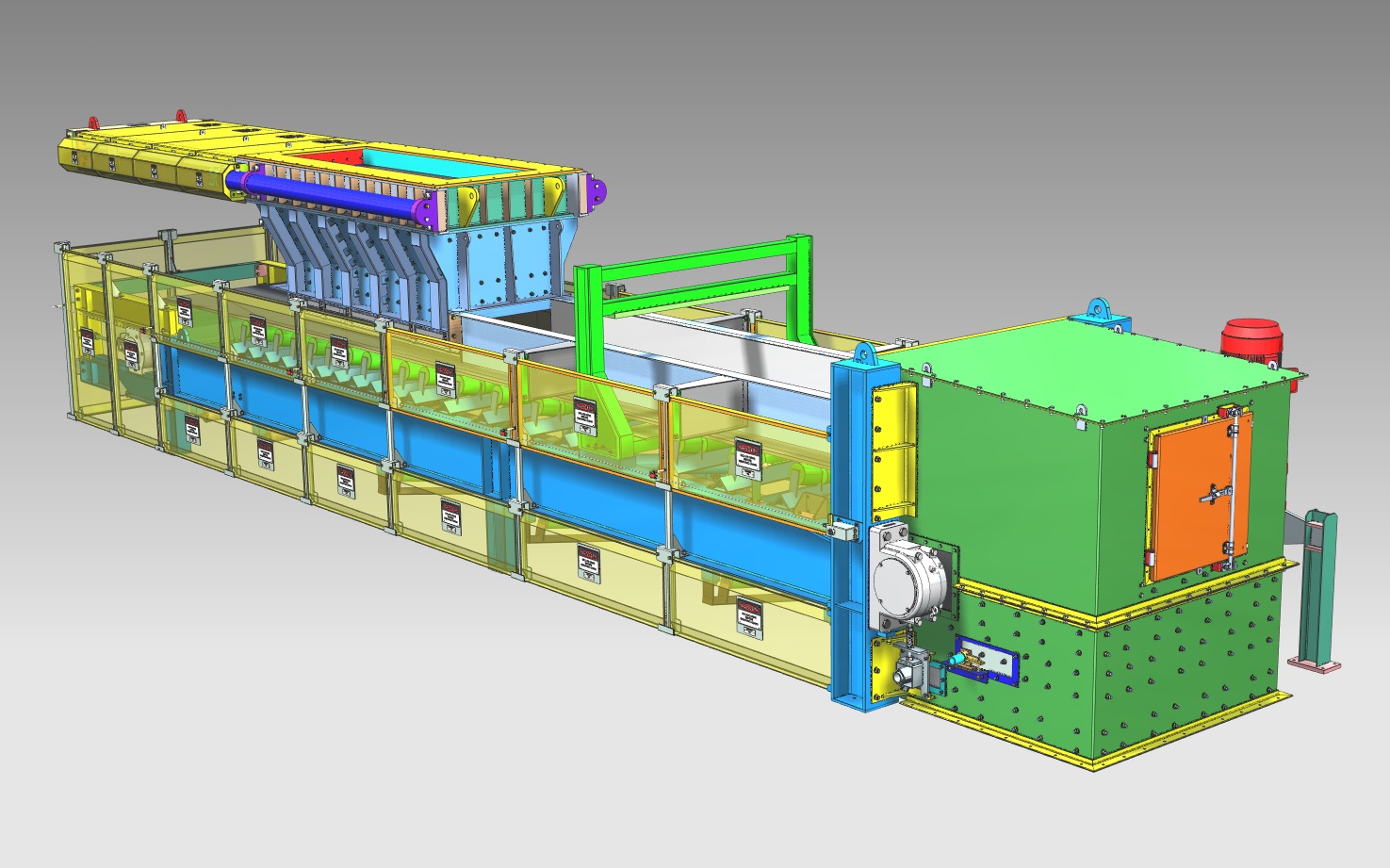

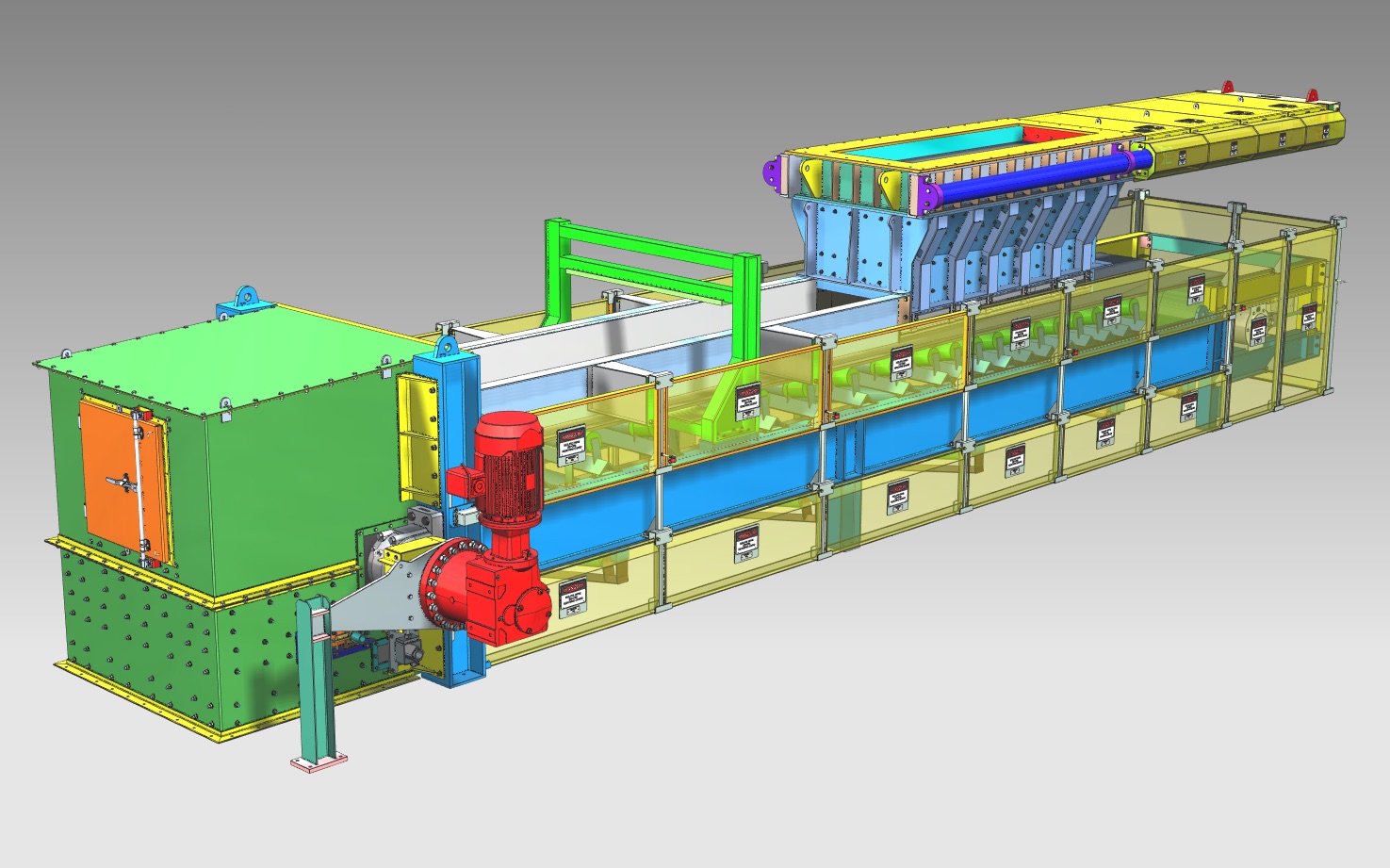

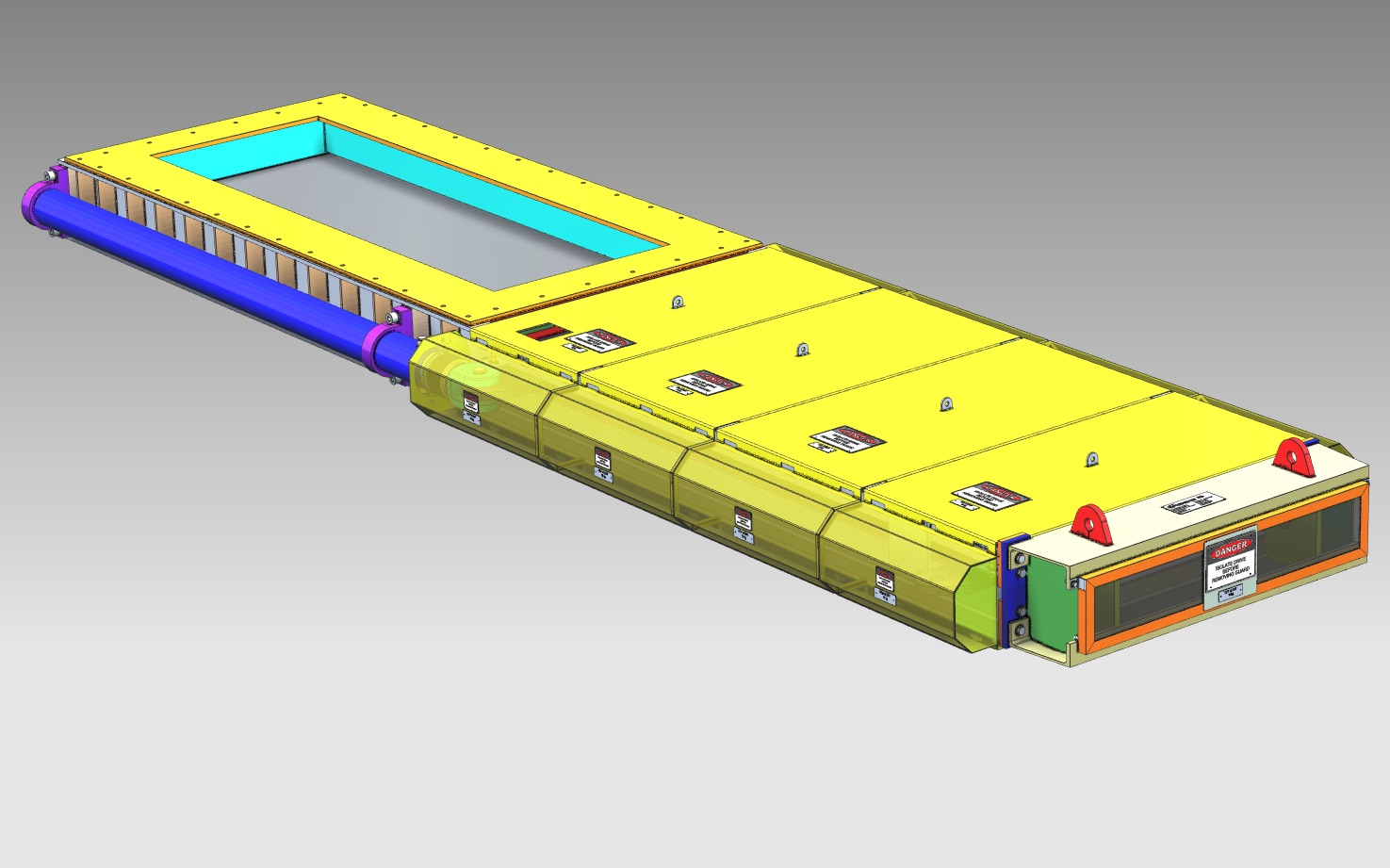

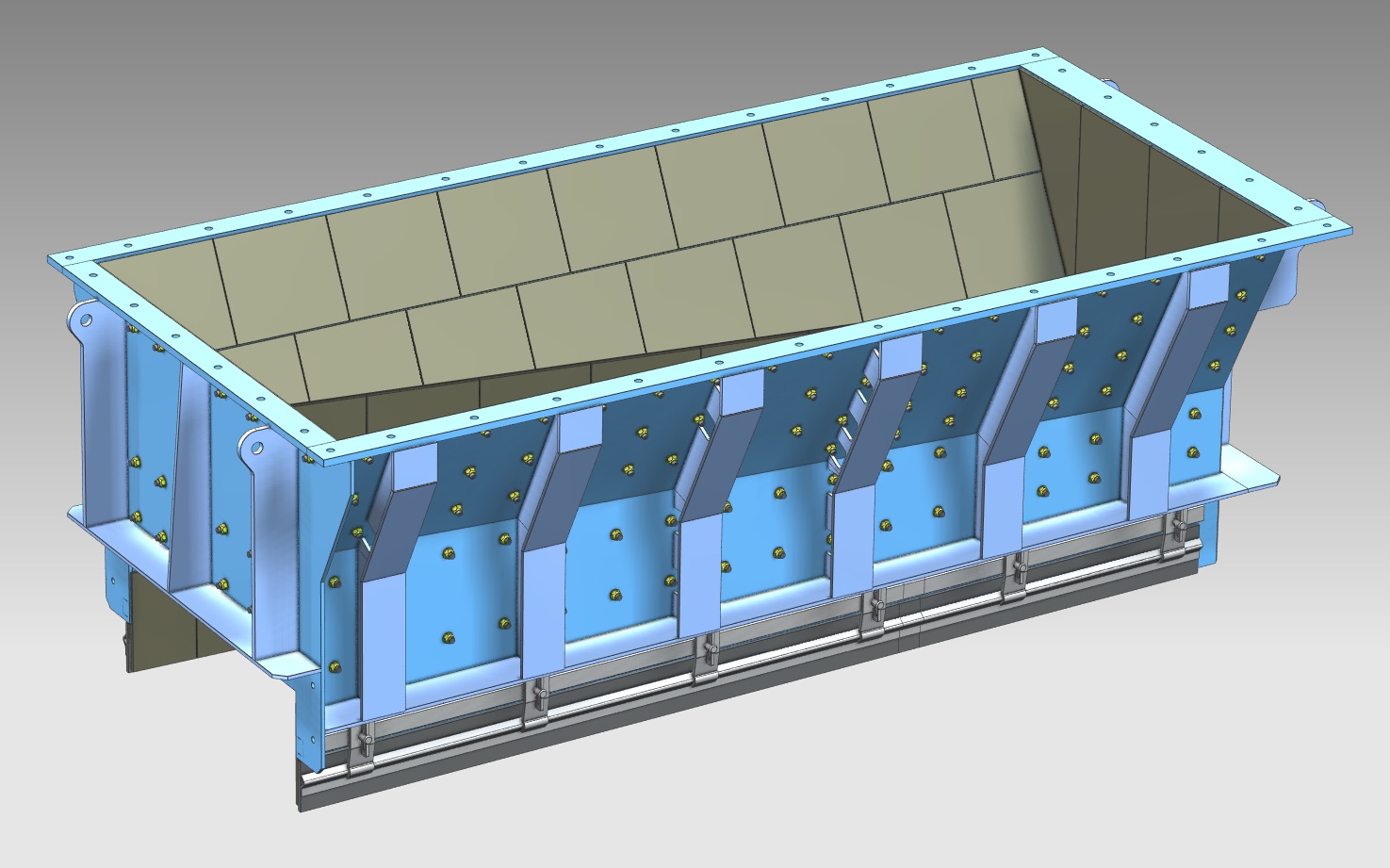

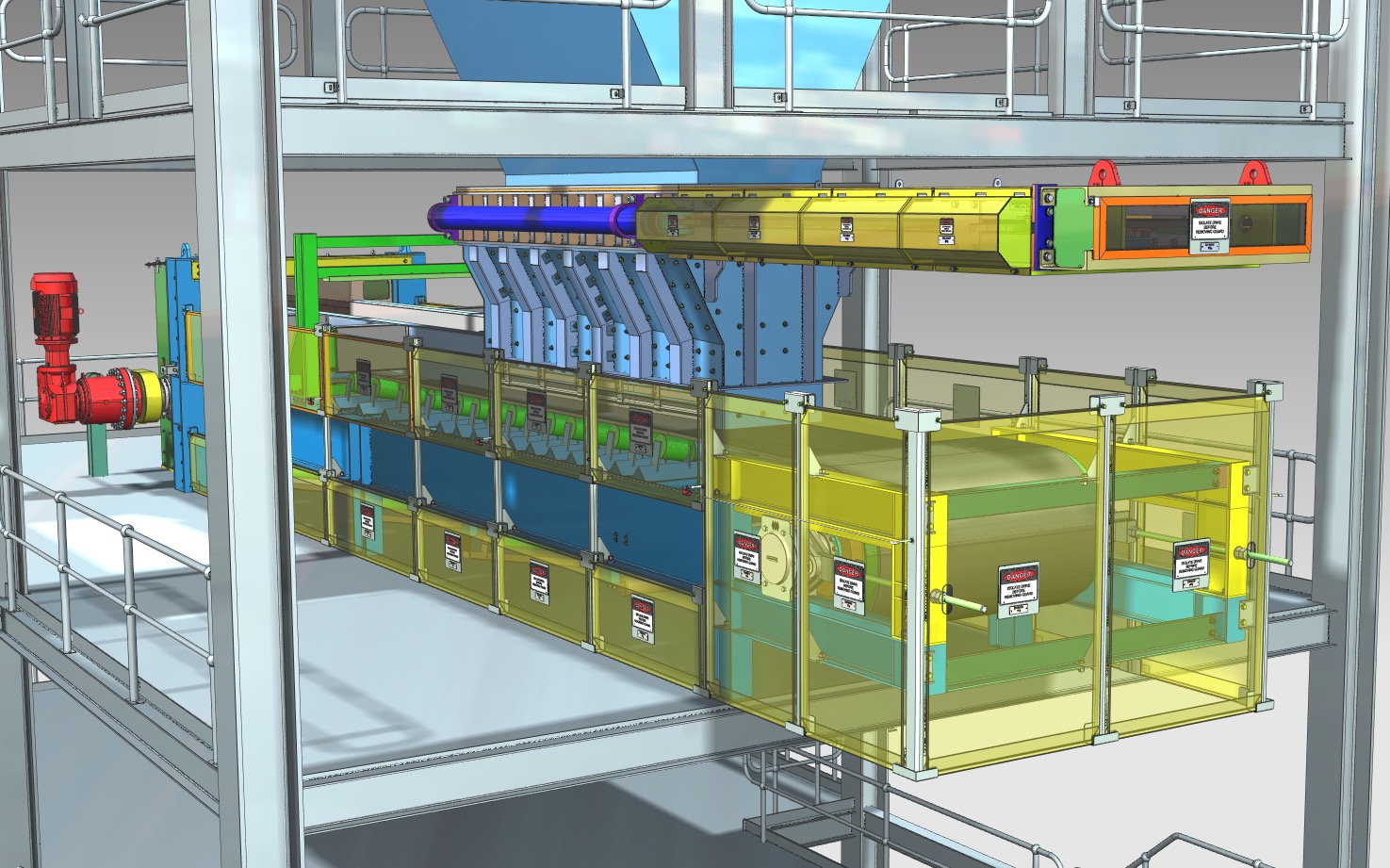

Scope of this project was to aid in the design, 3d model and provide general arrangement, installation, transport lifting, & manufacturing drawings for two (2) Belt Feeders to be installed side by side beneath the Rotary Car Dumper (RCD) discharge hoppers. The belt feeders are used to discharge from the two dump hoppers. Both Feeders were made identical. The material being moved was Koolyanobbing Iron Ore Lump (KL) (-31.5 +6.3mm) and Koolyanobbing Iron Ore Fines (KF) (-6.3mm) with feed rates of 400-1500 TPH required.

The Belt Feeders were supplied in assemblies which did not exceed 2.5m wide x 1.5m high (including packing), Model-IT was required to consider in the design features which will aid the removal and re-fitment of the head pulley.

Each Belt Feeder included the following items:

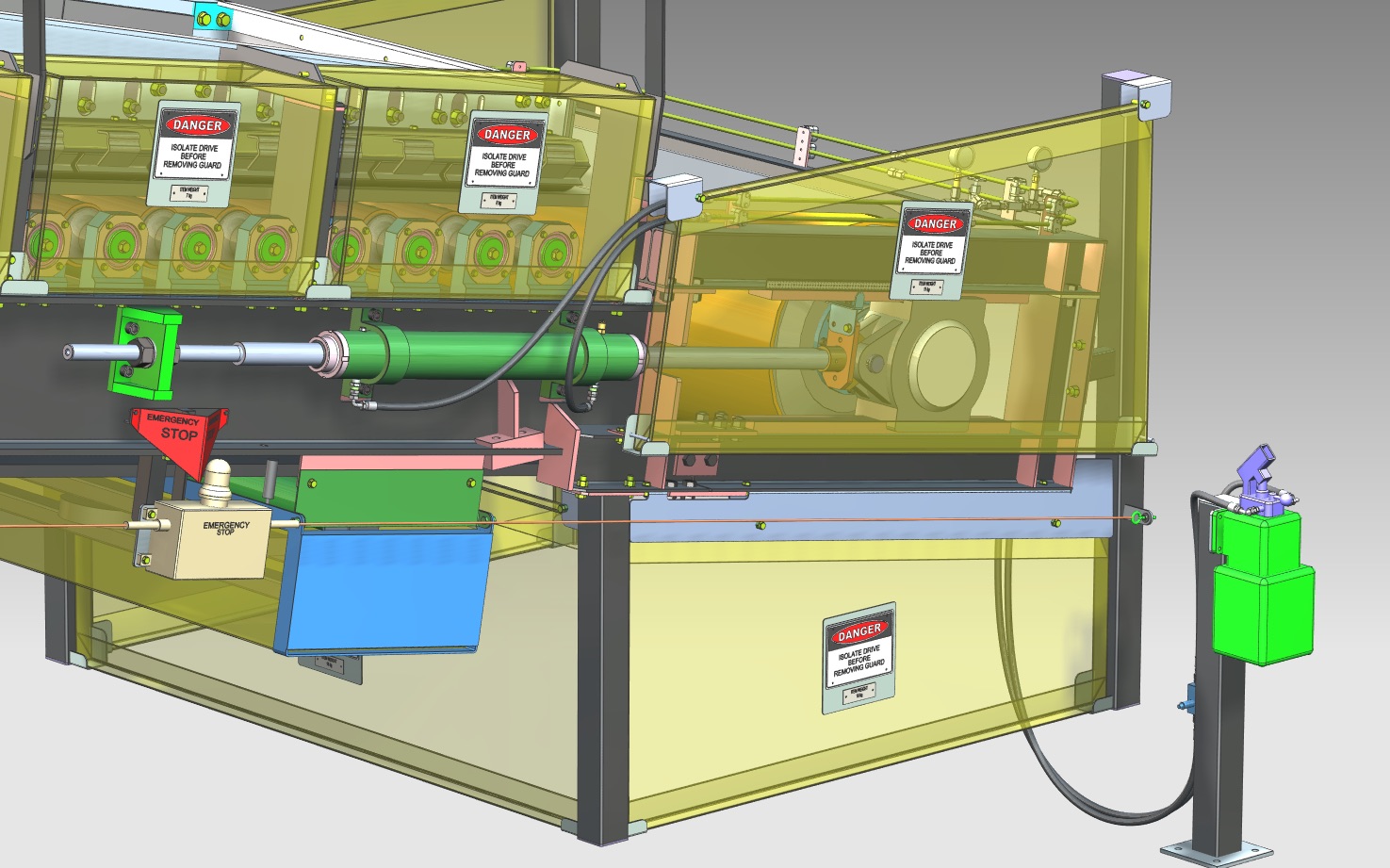

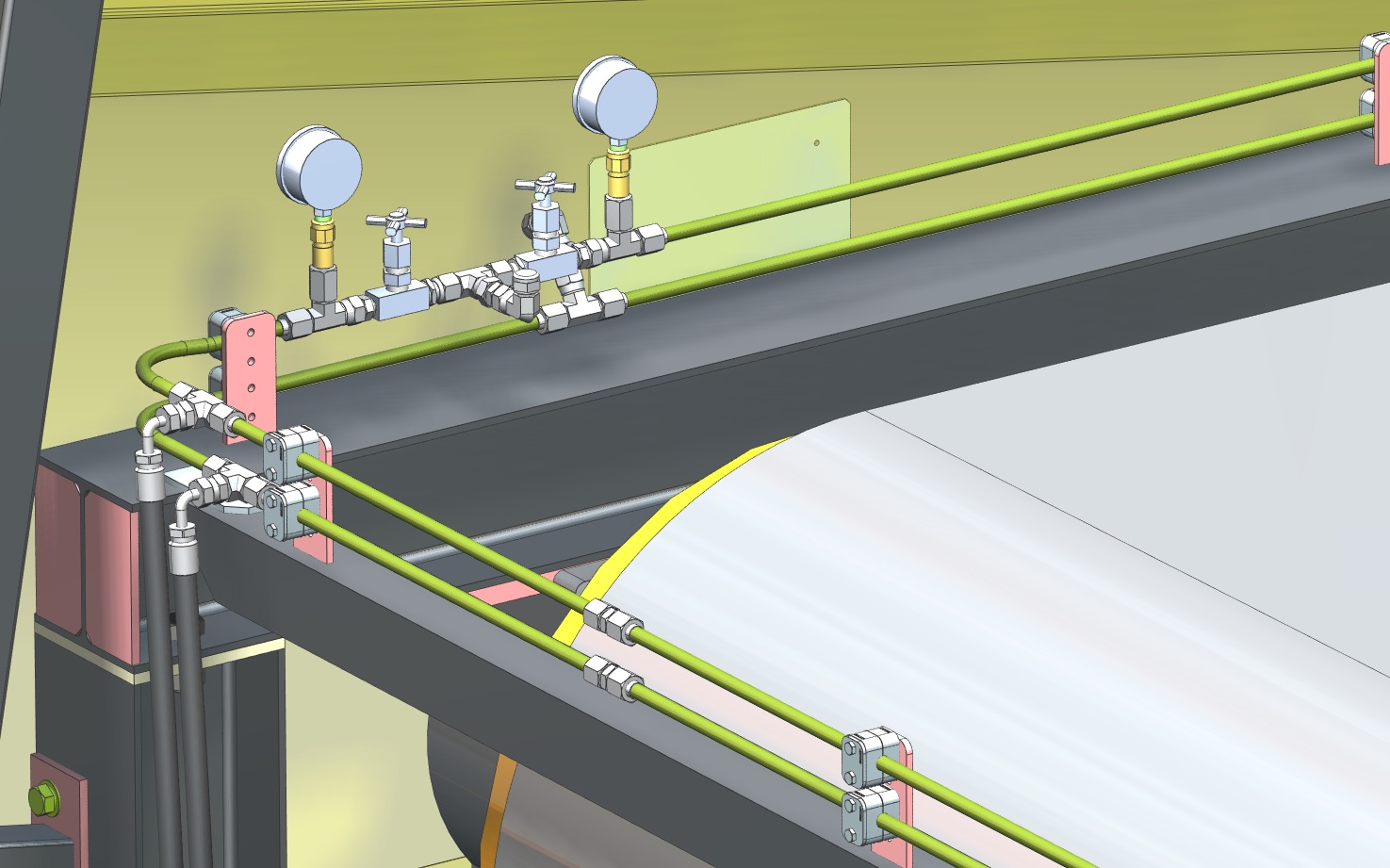

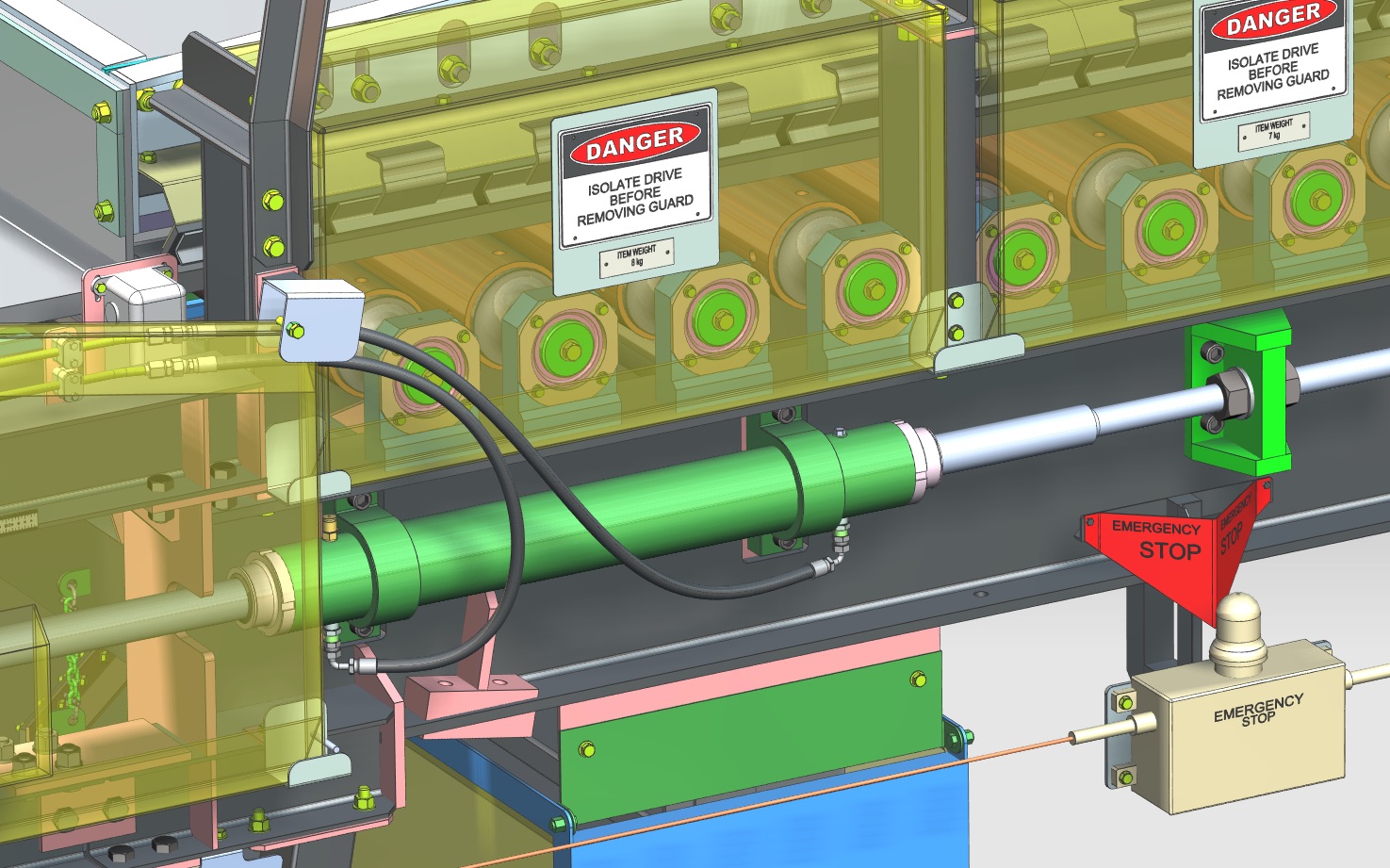

- Mechanical and Hydraulic Belt Tensioning System

- Adjustable Skirts

- Custom Idlers

- Dust Covers

- Removable head pulley

- Return Plough

- Underspeed, belt drift, rip detector and pull wire switches

- 3D Model of Feeders provided on completion of design along with .dwg files AS BUILTS.

Full safety covers and guarding was completed on all equipment and was designed to meet AS3990 Mechanical Equipment & AS3774 Bulk loading on Containers.